Our History

In the beginning.

The idea for Nix™ came in the form of a question: why were interior designers still carrying around tote bags filled with heavy fan decks and swatch books from individual brands? Why were professionals in all fields still eyeballing color?

Color can be greatly affected by ambient lighting conditions and human error – problem that can be time consuming and costly. We knew there had to be a way to solve these problems. After consulting professionals in the industry, we validated our idea and knew that there was a need for a better solution.

At the same time, another colleague of ours was doing incredible work at a local hospital with burn victims and patients with other severe skin disorders. Her business was to consult with patients and create custom makeup that perfectly blended with the patients’ natural skin tones.

To support her work, she was looking for an accurate and inexpensive color sensor that would eliminate the need for the costly manual color matching. It would revolutionize her business model while allowing her to help patients from all over the world. We thought this was a noble idea and it inspired us to start full-time research and development on a product that has now become today’s leading color measurement tool.

Commercial Launch

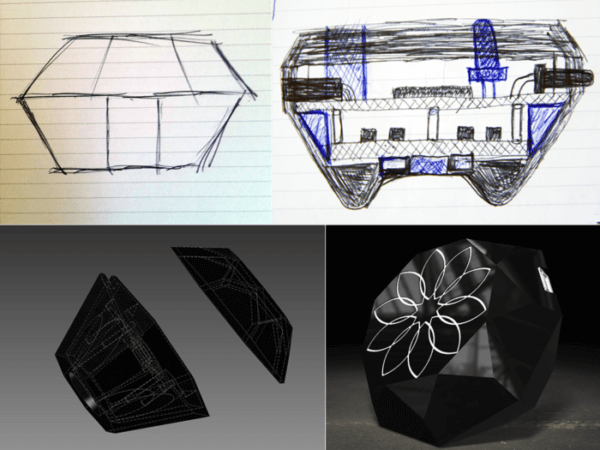

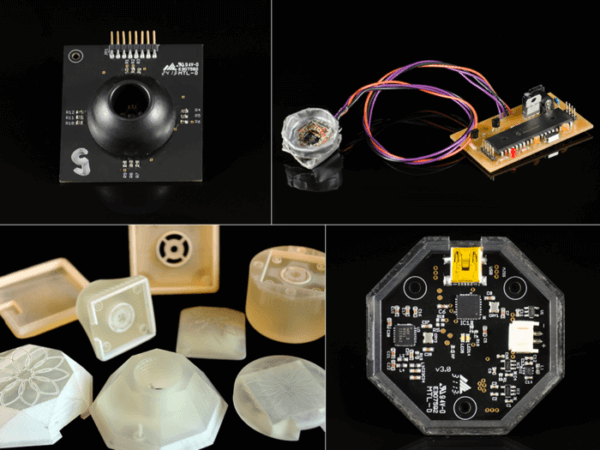

Six months after our initial funding and countless prototypes later, the final Nix prototype was born. It was through our successful Kickstarter campaign that we were able to fund the production of the first commercial prototype of the Nix Color Sensor.

Through customer feedback and industry advice we were able to optimize our product and software, offering features that were more useful to our customers. With that we were able to release our flagship product, the Nix Pro Color Sensor, to professionals, tech enthusiasts, and designers in over 50 countries world-wide.

Growth and Expansion

Just three years after our initial commercial release, we launched the Nix Mini Color Sensor– the first colorimeter of its kind to offer compact color matching to consumers across the globe. This low-cost device attracted a wider audience and provided infinite creative uses, even winning the German Design Award for high quality product design.

Today, we have a line of color sensors for every professional in every industry. You can learn more about how we’re revolutionizing the world of color with our Nix Mini 2, Nix Pro 2 and Nix Quality Control kit here.